SY-RBT

Triple Cone Mixer

The Triplicity-cone Mixer (SY-RBT) is designing of three-body mixing chambers, one cone at top, one cone at bottom and one cone at center of body. Because three-body mixing chambers create the S-shape tank to increase the mixing quality and production. The material inside the SY-RBT is moving in three dimensional motions to allow the material mixing evenly without material sticky in the inner wall. And because the chamber is rotated at lower speed, so the material inside the chamber would not be damage and effect by high temperature.

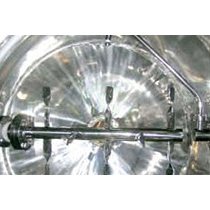

- This machine is improvement mechanism of traditional duplicity-cone mixer. The body of mixing chamber has three parts, one cone at the top, one cone at the bottom and one cone at the center of body. With those three parts, the machine has forming on S-shape mixed tank in order to improve mixing result. Turbulence board, turbulence ball, mixing blade, high-speed dispersing device, crushing blade, pressurize liquid-spraying device, vacuum drying device, vacuum filter, and CIP cleaning device, can be install inside the mixing chamber.

- Standard operation is feeding raw materials from the top of the cone and discharge from the bottom, but by using batch rotation function, vacuum covering function or through the center of the cone, the bottom can be also used for feeding material automatically. This type of mixer is very suitable for mixing low specific gravity and high fluidity type crushing power or dyeing with small grains. The materials in the S-type tank are moving in three-dimensional motions to achieve well mixed.

- The standard mixed quantity is 40%~60% of total capacity. The purpose of Triplicity-Cone mixer is to mix raw materials evenly. In order to prevent materials adhering on the wall of inner tank, the tank surface has been polish and finish with 15 RA value. This mixer can connect to vacuum and operate at low temperature to achieve drying purpose. Because this mixer can rotate at low speed, so it will not damage products, and the quality of products will not change when the temperature is at high condition. The products will have high finish quality, and it's indispensable equipment for chemical industry.

Features

- It is an improvement of the traditional duplicity-con mixer. The center is a round slant post, the top and bottom is conical shape, and forming and S-shape mixing tank. In order to improve mixing result, may equip turbulence board, turbulence ball, mixing blade, high speed dispersing, crushing blade, spraying liquid compression device, vacuum drying device, vacuum filter, and CIP cleaning device, etc. Inside the tank.

- Standard operation is by feeding raw materials from the top and discharge from the bottom. May also use the bottom to automatically feed materials by batch rotation, vacuum coveying, and through the center of the cone. The type of mixer si very suitable for mixing crushing power with fluidity and small specific gravity or dyeing and mixing small grains. The materials in the tank are mixed in a five-forms. The materials in the tank are mixed in a five-forms three-dimensional motion. Standard mixing quantity is 40%~60% of its total capacity.

- The prupose for Triplicity-Come Mixer is for even mixing is for even mixing for materials, especially to pretend adhering on the wall of tank interior, and for 320 frit size boff finsh May also coordinate with vaxuum drying and operate at low temperature, using slow rotation crystal, not easily wom. The product won't deform due to high temperature. High quality, able to produce uniform product. It is an equipemnt that chemical industry should posess.

Usaga

Dry-powder, Semi-dry powder and granules