WORLDWIDE

Home / Product Line

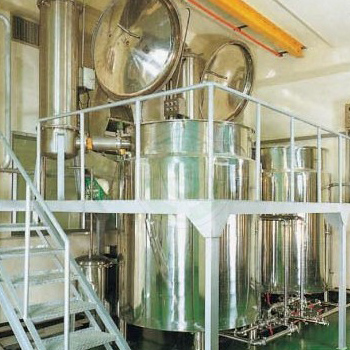

Mixing & Blending Tank

Shang-Yuh Machine Co., Ltd. is committed to developing Mixing & Blending Tank that ultimately create innovative products that exceed customer expectations. We are the global leader in machinery & industrial supplies. We develop, manufacture and distribute groundbreaking Mixing / Blending Equipment that shatter the status quo and help customers gain and maintain a competitive edge. We believe that our Mixing & Blending Tank have very great potential for this type of development in machinery & industrial supplies industry. Shang-Yuh Machine Co., Ltd. is committed to developing Mixing & Blending Tank that ultimately create innovative products that exceed customer expectations.

SY-ST

Emulsifying, Dispersing, Mixing/Scrape Tank

- Hermetically sealed type milk storage and eccentric stirrer design can create fluid convection to prevent sedimentation, and keep high quality of products. Cold water cooling device, automatic temperature controller, clean-in-place and air-filter are all conform to GMP requirement.

- 3-lager vessel is using SUS material, and automatic temperature control, digital indication, and adjustable step-less speed emulsification stirring are available in this tank. Operation options include vacuuming, heating, cooling, pressurizing, conditioning, stirring, emulsification, distribution, and defoaming. The product can be preserved longer treated by vacuum emulsify, mixing, scrape device.

SY-ST

Agitating Tank Device

The asepsis preparation machine is a highly efficient homogenizing mixer. With positive and negative magnetic forces, the mixer rotates direction could be change instantly. Because the mixer is installed at bottom of vessel, so the mixing blade could be easy to remove and change to different type of blade and no leak problem caused. The bearing house and mixer have self-cleaning function to achieve CIP/SIP requirement.

- Magnetic mixing vessel is a highly efficient homogenizing mixer and specifically designed for sterilized medicine, blood medicine, cell cultivation, fermentation and vaccine processes.

- By magnetic positive and negative transmission forces ,the mixing power and direction could be multiplied and reversed instantly respectively. The mixing is completely sealed, therefore, no cross contamination exists.

- With the magnetic transmission installed at the bottom of vessel, and separation plate to separate the inside of the vessel from outside so there is no seal leak problem. The blades are easy to disassemble and assemble. The bearing house and mixer have self-cleaning function to achieve CIP/SIP requirement.

SY-ST

Pressure Mixing Tank

The asepsis preparation machine is a highly efficient homogenizing mixer. With positive and negative magnetic forces, the mixer rotates direction could be change instantly. Because the mixer is installed at bottom of vessel, so the mixing blade could be easy to remove and change to different type of blade and no leak problem caused. The bearing house and mixer have self-cleaning function to achieve CIP/SIP requirement.

- Magnetic mixing vessel is a highly efficient homogenizing mixer and specifically designed for sterilized medicine, blood medicine, cell cultivation, fermentation and vaccine processes.

- By magnetic positive and negative transmission forces ,the mixing power and direction could be multiplied and reversed instantly respectively. The mixing is completely sealed, therefore, no cross contamination exists.

- With the magnetic transmission installed at the bottom of vessel, and separation plate to separate the inside of the vessel from outside so there is no seal leak problem. The blades are easy to disassemble and assemble. The bearing house and mixer have self-cleaning function to achieve CIP/SIP requirement.

SY-ST

Preparation Tank

- Hermetically sealed type milk storage and eccentric stirrer design can create fluid convection to prevent sedimentation, and keep high quality of products. Cold water cooling device, automatic temperature controller, clean-in-place and air-filter are all conform to GMP requirement.

- 3-lager vessel is using SUS material, and automatic temperature control, digital indication, and adjustable step-less speed emulsification stirring are available in this tank. Operation options include vacuuming, heating, cooling, pressurizing, conditioning, stirring, emulsification, distribution, and defoaming. The product can be preserved longer treated by vacuum emulsify, mixing, scrape device.

SY-ST

Vertical type deployment mixing tank

- Hermetically sealed type milk storage and eccentric stirrer design can create fluid convection to prevent sedimentation, and keep high quality of products. Cold water cooling device, automatic temperature controller, clean-in-place and air-filter are all conform to GMP requirement.

- 3-lager vessel is using SUS material, and automatic temperature control, digital indication, and adjustable step-less speed emulsification stirring are available in this tank. Operation options include vacuuming, heating, cooling, pressurizing, conditioning, stirring, emulsification, distribution, and defoaming. The product can be preserved longer treated by vacuum emulsify, mixing, scrape device.

SY-ST

Extraction System

- Hermetically sealed type milk storage and eccentric stirrer design can create fluid convection to prevent sedimentation, and keep high quality of products. Cold water cooling device, automatic temperature controller, clean-in-place and air-filter are all conform to GMP requirement.

- 3-lager vessel is using SUS material, and automatic temperature control, digital indication, and adjustable step-less speed emulsification stirring are available in this tank. Operation options include vacuuming, heating, cooling, pressurizing, conditioning, stirring, emulsification, distribution, and defoaming. The product can be preserved longer treated by vacuum emulsify, mixing, scrape device.

Sterile agitating tank with CIP/SIP System

The asepsis preparation machine is a highly efficient homogenizing mixer. With positive and negative magnetic forces, the mixer rotates direction could be change instantly. Because the mixer is installed at bottom of vessel, so the mixing blade could be easy to remove and change to different type of blade and no leak problem caused. The bearing house and mixer have self-cleaning function to achieve CIP/SIP requirement.

- Magnetic mixing vessel is a highly efficient homogenizing mixer and specifically designed for sterilized medicine, blood medicine, cell cultivation, fermentation and vaccine processes.

- By magnetic positive and negative transmission forces ,the mixing power and direction could be multiplied and reversed instantly respectively. The mixing is completely sealed, therefore, no cross contamination exists.

- With the magnetic transmission installed at the bottom of vessel, and separation plate to separate the inside of the vessel from outside so there is no seal leak problem. The blades are easy to disassemble and assemble. The bearing house and mixer have self-cleaning function to achieve CIP/SIP requirement.

SY-ST

Stainless steel raw material tank

The asepsis preparation machine is a highly efficient homogenizing mixer. With positive and negative magnetic forces, the mixer rotates direction could be change instantly. Because the mixer is installed at bottom of vessel, so the mixing blade could be easy to remove and change to different type of blade and no leak problem caused. The bearing house and mixer have self-cleaning function to achieve CIP/SIP requirement.

- Magnetic mixing vessel is a highly efficient homogenizing mixer and specifically designed for sterilized medicine, blood medicine, cell cultivation, fermentation and vaccine processes.

- By magnetic positive and negative transmission forces ,the mixing power and direction could be multiplied and reversed instantly respectively. The mixing is completely sealed, therefore, no cross contamination exists.

- With the magnetic transmission installed at the bottom of vessel, and separation plate to separate the inside of the vessel from outside so there is no seal leak problem. The blades are easy to disassemble and assemble. The bearing house and mixer have self-cleaning function to achieve CIP/SIP requirement.

SY-SS

CIP Device

The asepsis preparation machine is a highly efficient homogenizing mixer. With positive and negative magnetic forces, the mixer rotates direction could be change instantly. Because the mixer is installed at bottom of vessel, so the mixing blade could be easy to remove and change to different type of blade and no leak problem caused. The bearing house and mixer have self-cleaning function to achieve CIP/SIP requirement.

- Magnetic mixing vessel is a highly efficient homogenizing mixer and specifically designed for sterilized medicine, blood medicine, cell cultivation, fermentation and vaccine processes.

- By magnetic positive and negative transmission forces ,the mixing power and direction could be multiplied and reversed instantly respectively. The mixing is completely sealed, therefore, no cross contamination exists.

- With the magnetic transmission installed at the bottom of vessel, and separation plate to separate the inside of the vessel from outside so there is no seal leak problem. The blades are easy to disassemble and assemble. The bearing house and mixer have self-cleaning function to achieve CIP/SIP requirement.

SY-ST

Magnetic Mixer Device

The asepsis preparation machine is a highly efficient homogenizing mixer. With positive and negative magnetic forces, the mixer rotates direction could be change instantly. Because the mixer is installed at bottom of vessel, so the mixing blade could be easy to remove and change to different type of blade and no leak problem caused. The bearing house and mixer have self-cleaning function to achieve CIP/SIP requirement.

- Magnetic mixing vessel is a highly efficient homogenizing mixer and specifically designed for sterilized medicine, blood medicine, cell cultivation, fermentation and vaccine processes.

- By magnetic positive and negative transmission forces ,the mixing power and direction could be multiplied and reversed instantly respectively. The mixing is completely sealed, therefore, no cross contamination exists.

- With the magnetic transmission installed at the bottom of vessel, and separation plate to separate the inside of the vessel from outside so there is no seal leak problem. The blades are easy to disassemble and assemble. The bearing house and mixer have self-cleaning function to achieve CIP/SIP requirement.

SY-ST

Magnetic Mixer with Load Cell Device

The asepsis preparation machine is a highly efficient homogenizing mixer. With positive and negative magnetic forces, the mixer rotates direction could be change instantly. Because the mixer is installed at bottom of vessel, so the mixing blade could be easy to remove and change to different type of blade and no leak problem caused. The bearing house and mixer have self-cleaning function to achieve CIP/SIP requirement.

- Magnetic mixing vessel is a highly efficient homogenizing mixer and specifically designed for sterilized medicine, blood medicine, cell cultivation, fermentation and vaccine processes.

- By magnetic positive and negative transmission forces ,the mixing power and direction could be multiplied and reversed instantly respectively. The mixing is completely sealed, therefore, no cross contamination exists.

- With the magnetic transmission installed at the bottom of vessel, and separation plate to separate the inside of the vessel from outside so there is no seal leak problem. The blades are easy to disassemble and assemble. The bearing house and mixer have self-cleaning function to achieve CIP/SIP requirement.

Shang-Yuh Machine Co., Ltd., the world’s leading manufacturer of Mixing & Blending Tank, is positioned at the leading edge of innovation and service, providing the most comprehensive Mixing & Blending Tank solutions packages to its customers via a portfolio of highly recognized brands. We are a global manufacturer of high quality Mixing & Blending Tank and our company's internal strategy to continually improve quality and delivery meant the Mixing & Blending Tank was a product fit for the customers. If you are looking for Mixing & Blending Tank manufacturing company, let us be your answer.

Related Product Categories